2c3200 ошибка bmw n57

Обновлено: 06.07.2024

Hi All,

This error has reappeared after a days driving.

I cleared it earlier today took a short drive and no error, then a longer drive and it shows up again.

Anyone any experience with this error, I have replaced Swirls Flaps on E60 and E70 before including cleaning intakes and EGR delete.

But that was for prevention, on my 2015 X5 F15 sDrive25d I didn't expect it to have swirl flaps.

The diagnostics show the air intake is not whats expected, first screenshot is what it currently reads, the 2nd is what ISTA says the reading should be like.

Any advice before I start tracking that controller?

Just researching this and a few YouTube videos show swirl flaps are internal to the manifold until E Series.

So not easy to remove it replace, but before I start that was hoping someone might have been through this issue and can offer some advise?

Have you removed the flaps and left just the shaft as from what I can see it doesn't look to easy to remove without breaking them, unlike the external rod activated on the E Series?

For anyone who is interested.

I removed the intake manifold and the swirl flaps.

As ISTA reports the actual arm that connects to the actuator was broken.

They where VERY badly blocked up, I suspect they where so caked in carbon and dirt that the arm broke as they could no longer fully close without catching on the edges.

So its sorted now, you have to reset the Swirl Flap actuator BEFORE replacing them using ISTA, I assume this is to reset the amount of movement they are allowed and resets them to fully open and close again.

For anyone who is interested.

I removed the intake manifold and the swirl flaps.

As ISTA reports the actual arm that connects to the actuator was broken.

They were VERY badly blocked up, I suspect they were so caked in carbon and dirt that the arm broke as they could no longer fully close without catching on the edges.

So its sorted now, you have to reset the Swirl Flap actuator BEFORE replacing them using ISTA, I assume this is to reset the amount of movement they are allowed and resets them to fully open and close again.

I had the same issue as you had around 75k miles, and the dealer had to replace everything after they messed up on something else and I ended up luckily not paying a dime.

Hi,

It's 80k and was a lot dirtier than I expected for the milage and engine model.

I cleaned out the manifold by soaking in petrol overnight then finished with a cleaner similar to what you posted, and installed a new swirl flap rail.

I am going to map the engine and do an EFT delete and block off the feed pipe into the manifold, the older E series had a vac pipe you could remove and block, this engine doesn't.

As not worth having the carbon built up again.

I took some pictures that I can post when I am home.

Hi, I got the same problem with swirl flaps. All was cleaned very carefully and errors still occurs. Did you manage with the problem?

Hi, I got the same problem with swirl flaps. All was cleaned very carefully and errors still occurs. Did you manage with the problem?

Hi only seeing this post now!

Did you get it sorted, assumed you did by now but if not read below.

You have to reset the swirl flap before replacing (or cleaning them) as I mentioned above, otherwise the error won't clear which is what happened me the first time.

So reset the controller, then remove the connector to the actuator, then reconnect and reset again (so the car things you reset it before removal if that makes sense by just disconnecting and reconnecting between resets.)

Hi only seeing this post now!

Did you get it sorted, assumed you did by now but if not read below.

You have to reset the swirl flap before replacing (or cleaning them) as I mentioned above, otherwise the error won't clear which is what happened me the first time.

So reset the controller, then remove the connector to the actuator, then reconnect and reset again (so the car things you reset it before removal if that makes sense by just disconnecting and reconnecting between resets.)

Has anybody actually deleted the swirl flaps on the F15 and if so what’s the benefit? See on the E Series quite a few people have. but it’s also different design.

Hi, could you tell me where I can find in ISTA the procedure for checking the swirl flaps as you did? Thank you in advance.

Uploaded a pic of how to reset the adaptions in ISTA, its the air mass adaptions that need resetting.

I've just gone through this and not managed to get rid of the 2C3200 error code. Followed the steps resetting before and after unplugging the swirl flap controller and that has not worked.

I have subsequently changed the swirl flap controller to no effect. Now i think there may be an issue with the swirl flaps themeselves or maybe how i have fitted them. I have had them out now 5 times and still cannot see anything obviously wrong or broken, is there anything i should be conscious of when assembling the swirl flaps into the manifold? All the swirl flaps look identical and as they were so clogged when i took them out i wasn't able to maintain the order even though they all look identical.

Its very weird the car seems to be restricted at first start up then if i turn it off and re-start it then the restriction is not there. The error code still maintains.

I have managed to run the swirl flap test and get identical results as IrishLad, but then after a few cycles of stopping/starting the car it appears the DDE turns off the swirl flap controller and then when you run the swirl flap test the blue line (flap position) just flat lines across the bottom and the controller doesn't move during the test.

Anyone else struggled with this?

I am in two minds to just remove the swirl flaps, fit a bung in the end of the shaft and have it mapped out.

Also the DDE is now complaining the DPF soot levels are high as as the regen is blocked because of the swirl flap error in the DDE Arrgg.

Did you manage to get this resolved in the end? I have exactly the same issue and symptoms that you have described. Restricted power on first start, followed by normal power if do a quick engine off/on again.

In terms of troubleshooting, I have followed the very same approach - took out the inlet manifold, cleaned-up the swirl flaps such that they were super smooth and free-moving when they got reinstalled. The arm-follower for the actuator is a bit fiddly so when it didn't work at first I thought I did something wrong here. However, I've since had this in and out a few times and I am certain it's installed correctly. I have also reset the adaptation on ISTA using the method described in this thread. With all this done, it still shows a flat blue line during a swirl-flap test. One other thing I tried was to remove the actuator from car and run the swirl-flap test with it loose; it does show the motor arm moving in free-air, which further adds to my confusion. I was going to buy a new swirl-flap controlled thinking that this has died due to fighting excessive load for a prolonged period but your experience suggests this is unlikely to be the case.

All this started as I having been getting quite a lot of smoke under acceleration and also occassionally when I go to accelerate, it hesitates, followed by a cloud of smoke from the exhaust. I gather the fuel injected is not being matched by the right amount of air. I was hoping this was swirl-flap related issue but I reckon it may be more - but still need to solve this first!

Any update you could provide would be greatly appreciated.

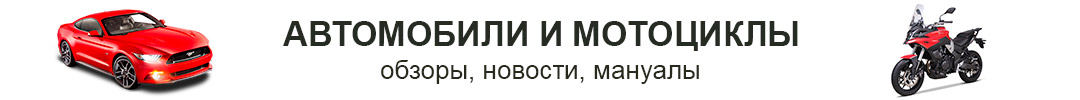

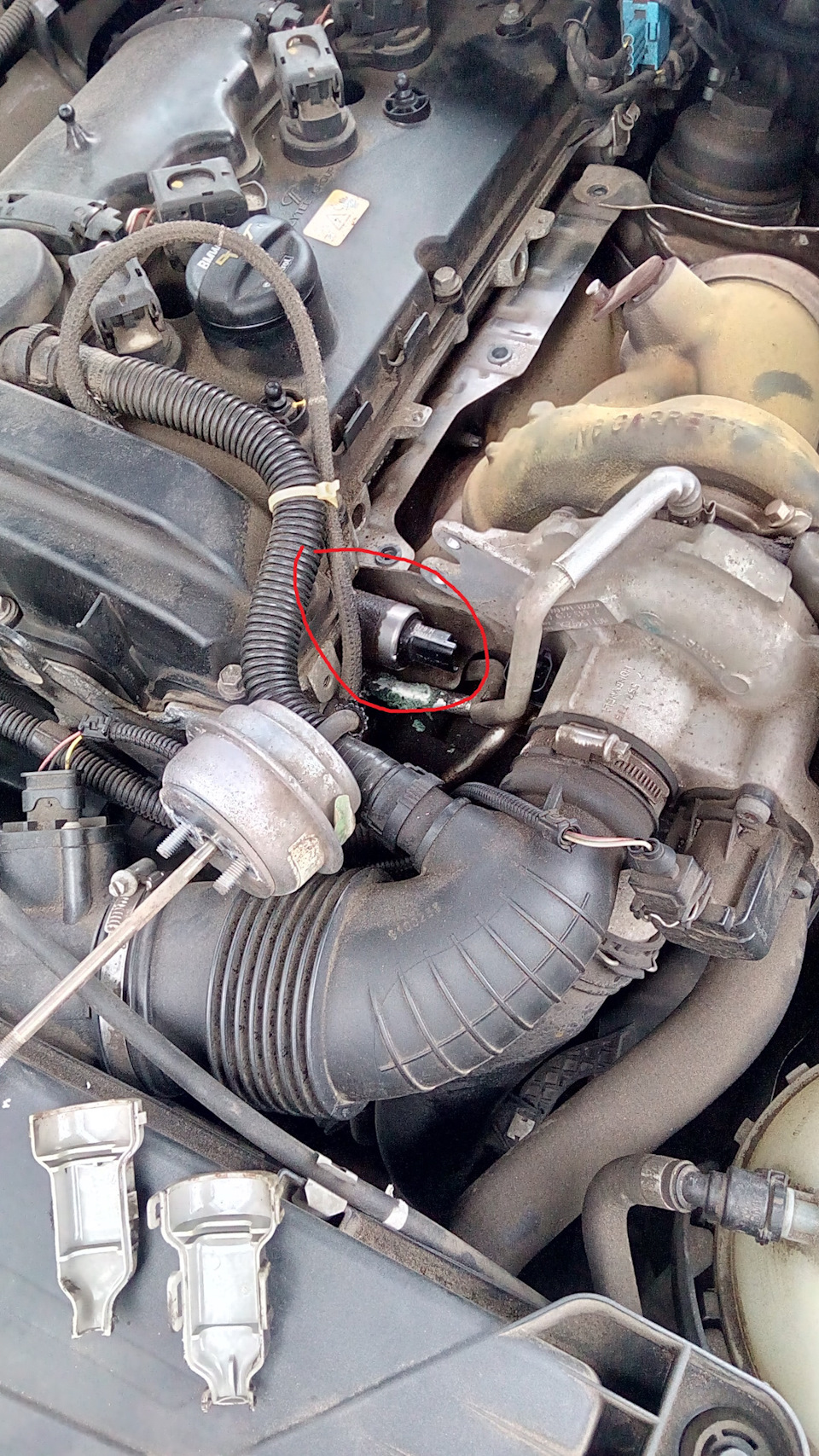

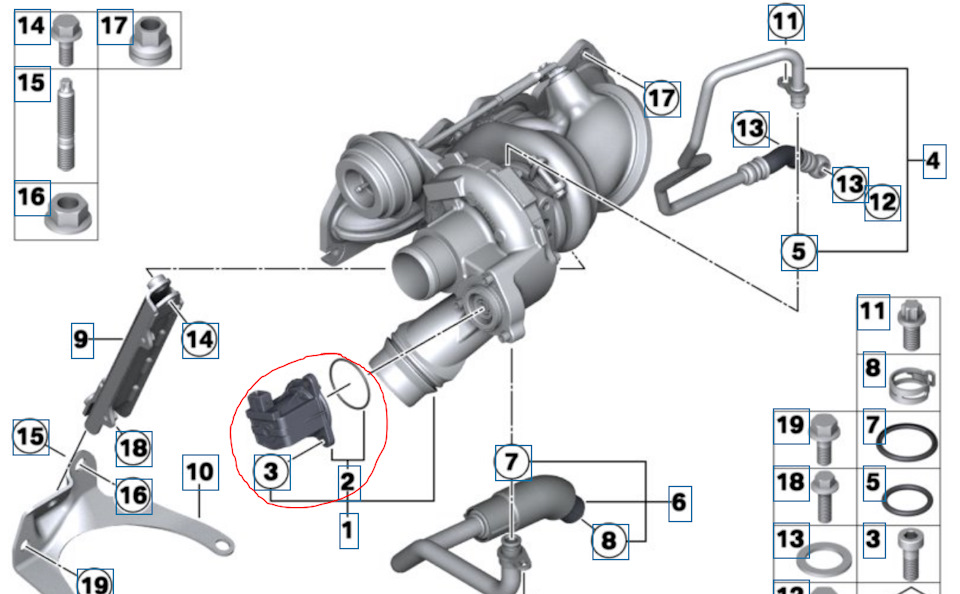

I figured out why we get the error code. Its because the swirl flap controller arm goes past its intended rest point (see pic) and triggers an internal switch that tells the DDE that the arm has detached from the swirl flaps.

Now ours haven't detached but the whole assembly must be rotating past its intended stop point. As you will be aware the system does have stop point in the full closed position but the motor is controlling the full open position on ours (default rest state of the motor) and shouldn't be. I can only conclude there should be a mechanical stop point that is worn/not working on ours. I tried to find where in the manifold within the swirl flap assembly there was something that was a functional stop point and couldn't see anything.

In the end i removed the swirl flaps, fitted a bung and then put a screw in the swirl flap controller (bodged. ) to mimic the stop point. I set the screw in the correct position using the test function in ista but its location is very easy to copy from the pic. You do lose some low down performance doing this but the car returns back to normal in function and error codes go and the swirl flap test works. I am about to have mine remapped to resolve the performance impact. Alternative solution is most likely a new inlet manifold.

I scored two lines on the controller in the pic to show where the arm rested without the screw and with the screw in place (position its meant to rest when assembled).

I know my controller had no issue as i replaced, that leaves the arms or the inlet being worn as the main candidates.

hope this helps.

I have also done some research on what creates the blocked swirl flap issue. Its definitely the combination of oil vapors from the rocker cover via the pcv valve and exhaust gases from the egr. The key is to stop the oil vapors, so i will be installing a oil catch can to prevent the sludge build up.

Дополнений к первой части так и не последовало в комментариях. Наверное я охватил максимальное количество проблем касательно охлаждающей системы. А скорее всего подобные посты никому не интересны ведь в них нет сисек :D

Привод. Продолжайте движение с малой скоростью.

Симпотомы: ТРТРТРТТР. Затарахтела, затроила. Сильная вибрация по кузову. Загорелся чек.

Причин может быть несколько. Самая безобидная из них это выход катушки из строя. В идеале подключить ноут с рейнгольдом, прочитать ошибки. Если ноута нет то лучше на такой случай иметь запасную катушку. Методом тыка определить вышедшую из строя, а именно, вытащить катушку с первого цилиндра и заменить на новую. Нумерация начинается от бампера. Если все так же трясет значит вышла из строя не первая. Ставим назад старую и меняем теперь катушку на втором цилиндре. Выполнять подобные действия пока не обнаружится диверсант)

Номер детали: DELPHI GN1057212B1

Стоимости замены катушки в сервисе "евроавто" по СПб составляет 660р! 28.05.2018

И это не учитывая компьютерной диагностики. Вывод делайте сами.

Ошибка привода. Полная мощность больше недоступна

Симптомы: Пропадает тяга. Ошибка 130204, 120408.

Замена клапана Vanos 9825813780 — оригинал, но можно поставить от Peugeot . Дешевле на 40%. Тот же самый клапан. В общем то это пожалуй главная информация касательно замены клапана. Да, есть люди которые об этом не знают.

Сложность его замены заключается в труднодоступности, но если руки есть и голова сделать будет ерунда.

Ошибка привода. Полная мощность больше недоступна.

Симптомы: недостаточное давление наддува, по ощущением авто теряет 40% лс. Код 12308.

Возможен выход из строя преобразователя давления Pierburg номер — 7.01777.17.0.

Но сперва лучше проверить состояние трубок. Начинаем продувать трубки (от преобразователя давления их идёт 2, одна на ресивер на клапанной крышке) эта трубка стала пластиковая, из-за высокой температуры от турбины высохла и треснула в нескольких местах.

Есть вариант еще дешевле…MEAT&DORIA в коробочке лежит все тот же Pierburg . MEAT DORIA 9339 цена 2300 на 30.08.2018

Материал: ребята, извините. я не сохранил

Симптомы: Тачка не валит. иногда слышен свист из под капота при движении. Зачастую ошибка при этом не появляется.

Если ошибка все таки выскочила то подключаем комп. Ошибка недостаточного давления.

Находим электромагнитный клапан. Снимаем его и разбираем. Проверяем целостность мембраны. Если порвана то мы правильно нашли виновника.

Номер оригинальной детали: 11657602293 Хотя есть китай, а так же австралийский клапан. Но там свои нюансы.

Симптомы: колбасит на холодную. После прогрева все проходит.

Причин несколько. Назову часть из них.

— свечи

— катушки

— форсунки

— бензин

— патрубки

На счет патрубков отдельная тема. С виду они в норме, а по факту от времени рассохлись и где то подсасывают воздух, что и является причиной троения.

Трубопровод чистого воздуха 1371 7597 586

Шланг для прокачки (верхний) 1115 7608 144

Трубопровод вентиляции (нижний) 1115 7614 690

Симптомы: периодически сильные задержки реакции между нажатием на газ, тряска, иногда вылезает джекичан.

Двигатель высокотемпературный. работать при температуре 120 градусов для него нормально, но из за этого со временем рассыхаются, портятся детали. Виновница этого — турбина, которая испепеляет все что ее окружает) Одна из умирающих деталей это Трубопровод чистого воздуха. Обычно его добивают меняя воздушный фильтр. Если во время не заметить, то часть от трубы может засосать турбиной…думаю дальше пояснять не требуется)

Симптомы: тяжелый руль, скрежет при повороте руля. Может выскочить ошибка.

Больше постов, чем про замену болтов на драйве, только если про переобувание и мытье авто. Но это не спасает от сломанных рулевых реек. Зачем люди тут сидят?)

Скорее всего отвалился моторчик рулевой рейки, а причина кроется в силуминовых болтах на которых он держится. От времени и реагентов болты сгнивают. Моторчик вываливается на защиту двигателя при этом может порвать ремешок, что внутри моторчика.

Hi All,

This error has reappeared after a days driving.

I cleared it earlier today took a short drive and no error, then a longer drive and it shows up again.

Anyone any experience with this error, I have replaced Swirls Flaps on E60 and E70 before including cleaning intakes and EGR delete.

But that was for prevention, on my 2015 X5 F15 sDrive25d I didn't expect it to have swirl flaps.

The diagnostics show the air intake is not whats expected, first screenshot is what it currently reads, the 2nd is what ISTA says the reading should be like.

Any advice before I start tracking that controller?

Just researching this and a few YouTube videos show swirl flaps are internal to the manifold until E Series.

So not easy to remove it replace, but before I start that was hoping someone might have been through this issue and can offer some advise?

Have you removed the flaps and left just the shaft as from what I can see it doesn't look to easy to remove without breaking them, unlike the external rod activated on the E Series?

For anyone who is interested.

I removed the intake manifold and the swirl flaps.

As ISTA reports the actual arm that connects to the actuator was broken.

They where VERY badly blocked up, I suspect they where so caked in carbon and dirt that the arm broke as they could no longer fully close without catching on the edges.

So its sorted now, you have to reset the Swirl Flap actuator BEFORE replacing them using ISTA, I assume this is to reset the amount of movement they are allowed and resets them to fully open and close again.

For anyone who is interested.

I removed the intake manifold and the swirl flaps.

As ISTA reports the actual arm that connects to the actuator was broken.

They were VERY badly blocked up, I suspect they were so caked in carbon and dirt that the arm broke as they could no longer fully close without catching on the edges.

So its sorted now, you have to reset the Swirl Flap actuator BEFORE replacing them using ISTA, I assume this is to reset the amount of movement they are allowed and resets them to fully open and close again.

I had the same issue as you had around 75k miles, and the dealer had to replace everything after they messed up on something else and I ended up luckily not paying a dime.

Hi,

It's 80k and was a lot dirtier than I expected for the milage and engine model.

I cleaned out the manifold by soaking in petrol overnight then finished with a cleaner similar to what you posted, and installed a new swirl flap rail.

I am going to map the engine and do an EFT delete and block off the feed pipe into the manifold, the older E series had a vac pipe you could remove and block, this engine doesn't.

As not worth having the carbon built up again.

I took some pictures that I can post when I am home.

Hi, I got the same problem with swirl flaps. All was cleaned very carefully and errors still occurs. Did you manage with the problem?

Hi, I got the same problem with swirl flaps. All was cleaned very carefully and errors still occurs. Did you manage with the problem?

Hi only seeing this post now!

Did you get it sorted, assumed you did by now but if not read below.

You have to reset the swirl flap before replacing (or cleaning them) as I mentioned above, otherwise the error won't clear which is what happened me the first time.

So reset the controller, then remove the connector to the actuator, then reconnect and reset again (so the car things you reset it before removal if that makes sense by just disconnecting and reconnecting between resets.)

Hi only seeing this post now!

Did you get it sorted, assumed you did by now but if not read below.

You have to reset the swirl flap before replacing (or cleaning them) as I mentioned above, otherwise the error won't clear which is what happened me the first time.

So reset the controller, then remove the connector to the actuator, then reconnect and reset again (so the car things you reset it before removal if that makes sense by just disconnecting and reconnecting between resets.)

Has anybody actually deleted the swirl flaps on the F15 and if so what’s the benefit? See on the E Series quite a few people have. but it’s also different design.

Hi, could you tell me where I can find in ISTA the procedure for checking the swirl flaps as you did? Thank you in advance.

Uploaded a pic of how to reset the adaptions in ISTA, its the air mass adaptions that need resetting.

I've just gone through this and not managed to get rid of the 2C3200 error code. Followed the steps resetting before and after unplugging the swirl flap controller and that has not worked.

I have subsequently changed the swirl flap controller to no effect. Now i think there may be an issue with the swirl flaps themeselves or maybe how i have fitted them. I have had them out now 5 times and still cannot see anything obviously wrong or broken, is there anything i should be conscious of when assembling the swirl flaps into the manifold? All the swirl flaps look identical and as they were so clogged when i took them out i wasn't able to maintain the order even though they all look identical.

Its very weird the car seems to be restricted at first start up then if i turn it off and re-start it then the restriction is not there. The error code still maintains.

I have managed to run the swirl flap test and get identical results as IrishLad, but then after a few cycles of stopping/starting the car it appears the DDE turns off the swirl flap controller and then when you run the swirl flap test the blue line (flap position) just flat lines across the bottom and the controller doesn't move during the test.

Anyone else struggled with this?

I am in two minds to just remove the swirl flaps, fit a bung in the end of the shaft and have it mapped out.

Also the DDE is now complaining the DPF soot levels are high as as the regen is blocked because of the swirl flap error in the DDE Arrgg.

Did you manage to get this resolved in the end? I have exactly the same issue and symptoms that you have described. Restricted power on first start, followed by normal power if do a quick engine off/on again.

In terms of troubleshooting, I have followed the very same approach - took out the inlet manifold, cleaned-up the swirl flaps such that they were super smooth and free-moving when they got reinstalled. The arm-follower for the actuator is a bit fiddly so when it didn't work at first I thought I did something wrong here. However, I've since had this in and out a few times and I am certain it's installed correctly. I have also reset the adaptation on ISTA using the method described in this thread. With all this done, it still shows a flat blue line during a swirl-flap test. One other thing I tried was to remove the actuator from car and run the swirl-flap test with it loose; it does show the motor arm moving in free-air, which further adds to my confusion. I was going to buy a new swirl-flap controlled thinking that this has died due to fighting excessive load for a prolonged period but your experience suggests this is unlikely to be the case.

All this started as I having been getting quite a lot of smoke under acceleration and also occassionally when I go to accelerate, it hesitates, followed by a cloud of smoke from the exhaust. I gather the fuel injected is not being matched by the right amount of air. I was hoping this was swirl-flap related issue but I reckon it may be more - but still need to solve this first!

Any update you could provide would be greatly appreciated.

I figured out why we get the error code. Its because the swirl flap controller arm goes past its intended rest point (see pic) and triggers an internal switch that tells the DDE that the arm has detached from the swirl flaps.

Now ours haven't detached but the whole assembly must be rotating past its intended stop point. As you will be aware the system does have stop point in the full closed position but the motor is controlling the full open position on ours (default rest state of the motor) and shouldn't be. I can only conclude there should be a mechanical stop point that is worn/not working on ours. I tried to find where in the manifold within the swirl flap assembly there was something that was a functional stop point and couldn't see anything.

In the end i removed the swirl flaps, fitted a bung and then put a screw in the swirl flap controller (bodged. ) to mimic the stop point. I set the screw in the correct position using the test function in ista but its location is very easy to copy from the pic. You do lose some low down performance doing this but the car returns back to normal in function and error codes go and the swirl flap test works. I am about to have mine remapped to resolve the performance impact. Alternative solution is most likely a new inlet manifold.

I scored two lines on the controller in the pic to show where the arm rested without the screw and with the screw in place (position its meant to rest when assembled).

I know my controller had no issue as i replaced, that leaves the arms or the inlet being worn as the main candidates.

hope this helps.

I have also done some research on what creates the blocked swirl flap issue. Its definitely the combination of oil vapors from the rocker cover via the pcv valve and exhaust gases from the egr. The key is to stop the oil vapors, so i will be installing a oil catch can to prevent the sludge build up.

Конструктивные особенности

Мотор получил новый закрытый блок цилиндров из алюминия, чугунные гильзы и вертикальное размещение клапанов. Свечи накаливания - керамические.

Коленвал конструктивно изменен под параметры нового блока цилиндров. Внутри новой головки блока - два распредвала.

Мотор получил турбину с интеркуллером - Garrett с изменяемой геометрией, что позволило получить более быстрый отклик на нажатие педали газа водителем.

Система питания Common Rail и пьезоэлектрические форсунки Bosch позволили оптимизировать сгорание топлива внутри цилиндров и уменьшить количество вредных выбросов, снизить топливный расход.

С предшественником M57 двигатель роднит впускной коллектор с вихревыми заслонками и система рециркуляции отработавших газов EGR. Двигатель соответствует экологическим нормам стандарта Евро 5, Евро 6.

Мотор получил систему управления Bosch DDE7.3.

Чтобы отодвинуть двигатель от капота, обезопасив пешеходов при ударе в случае аварии, привод ГРМ в N57 перенесли в заднюю часть мотора. Сам же привод - металлическая цепь с однорядной конструкцией. Срок ее жизни больше, чем на собрате, моторе BMW N47.

В результате конструкторам удалось создать мощный современный ДВС с впечатляющими мощностными характеристиками.

Мощность двигателя в зависимости от модификации составляет 204-381 л.с. при крутящем моменте от 450 до 740 Нм.

Устанавливают N57 на следующие модели БМВ:

- BMW 325d, 330d, 335d в кузове E90, F30

- BMW 430d, 435d в кузове F32

- BMW 525d, 530d, 535d, M550d в кузове F10

- BMW 640d в кузове F13

- BMW 730d, 740d, 750d в кузове F01

- BMW X3 в кузове F25

- BMW X4 в кузове F26

- BMW X5 в кузове E70, F15

- BMW X6 в кузове E71, F16

Вместе с N57 производитель выпускал и 4-цилиндровый дизельный N47, который фактически представляет собой тот же мотор за отсутствием двух цилиндров, с другой турбиной и системами выпуска и впуска.

С 2015 года планомерно N57 заменяют на новые дизели BMW B57.

Модификации двигателя

Эксплуатация N57

Расход топлива составляет 6,4 л по городу, 4, 9 л по трассе и 5,4 литра дизтоплива в смешанном режиме на 100 км пробега.

Расход масла на угар, заявленный производителем, составляет 700 мл на 1000 км.

Как и все современные двигатели BMW, мотор привередлив к качеству моторного масла и топлива. Масло стоит использовать исключительно 5W30, 5W40, желательно - рекомендуемое производителем.

Техническое обслуживание мотора N57 проводится каждые 15 тыс. км пробега. Сервисмены рекомендуют сократить этот регламент до 7-8 тыс. км.

Ресурс двигателя по оценкам владельцев и экспертов составляет 300+ тыс. км.

- Привод ГРМ также весьма надежен: цепь ходит в среднем по 200+ тыс. км.

- Турбина служит 200+ тыс. км, что весьма достойно.

Типичные неисправности

Двигатель N57 похож по конструкции и характеристикам на другие моторы N-семейства. У него также имеются специфические проблемы, характерные для данных турбодизелей.

Вихревые заслонки

В отличие от семейства M, здесь они рискуют не отломаться, улетев в двигатель - но закоксоваться и перестать вращаться. Как следствие - работа двигателя нарушается, на приборной панели владелец видит коды ошибок.

К такой ситуации приводит загрязненный клапан EGR. Его нужно регулярно чистить или заглушить. Часто владельцы сталкиваются с проблемой заклинившего клапана уже к 100 тыс. км. пробега.

Шум в подкапотном пространстве

Общая проблема с мотором N47, которая связана с износом демпфера коленвала спустя примерно 100 тыс. км пробега. Решение - замена детали.

Цепь ГРМ

Другая причина нетипичного шума из моторного отсека - на замену таким образом попросилась цепь привода ГРМ. Обычно это случается на пробеге порядка 200 тыс. км.

Итого

Моторы серии N57 - надежные мощные турбодизели, которые заслужили уважение автолюбителей по всему миру.

Если сократить рекомендуемый производителем срок обслуживания мотора вдвое, не экономить на расходниках и заправляться качественным топливом, N57 прослужит долго и порадует своими характеристиками владельца.

Не пропустите другие обзоры двигателей BMW N-серии:

Конструктивные особенности

Мотор получил новый закрытый блок цилиндров из алюминия, чугунные гильзы и вертикальное размещение клапанов. Свечи накаливания - керамические.

Коленвал конструктивно изменен под параметры нового блока цилиндров. Внутри новой головки блока - два распредвала.

Мотор получил турбину с интеркуллером - Garrett с изменяемой геометрией, что позволило получить более быстрый отклик на нажатие педали газа водителем.

Система питания Common Rail и пьезоэлектрические форсунки Bosch позволили оптимизировать сгорание топлива внутри цилиндров и уменьшить количество вредных выбросов, снизить топливный расход.

С предшественником M57 двигатель роднит впускной коллектор с вихревыми заслонками и система рециркуляции отработавших газов EGR. Двигатель соответствует экологическим нормам стандарта Евро 5, Евро 6.

Мотор получил систему управления Bosch DDE7.3.

Чтобы отодвинуть двигатель от капота, обезопасив пешеходов при ударе в случае аварии, привод ГРМ в N57 перенесли в заднюю часть мотора. Сам же привод - металлическая цепь с однорядной конструкцией. Срок ее жизни больше, чем на собрате, моторе BMW N47.

В результате конструкторам удалось создать мощный современный ДВС с впечатляющими мощностными характеристиками.

Мощность двигателя в зависимости от модификации составляет 204-381 л.с. при крутящем моменте от 450 до 740 Нм.

Устанавливают N57 на следующие модели БМВ:

- BMW 325d, 330d, 335d в кузове E90, F30

- BMW 430d, 435d в кузове F32

- BMW 525d, 530d, 535d, M550d в кузове F10

- BMW 640d в кузове F13

- BMW 730d, 740d, 750d в кузове F01

- BMW X3 в кузове F25

- BMW X4 в кузове F26

- BMW X5 в кузове E70, F15

- BMW X6 в кузове E71, F16

Вместе с N57 производитель выпускал и 4-цилиндровый дизельный N47, который фактически представляет собой тот же мотор за отсутствием двух цилиндров, с другой турбиной и системами выпуска и впуска.

С 2015 года планомерно N57 заменяют на новые дизели BMW B57.

Модификации двигателя

Эксплуатация N57

Расход топлива составляет 6,4 л по городу, 4, 9 л по трассе и 5,4 литра дизтоплива в смешанном режиме на 100 км пробега.

Расход масла на угар, заявленный производителем, составляет 700 мл на 1000 км.

Как и все современные двигатели BMW, мотор привередлив к качеству моторного масла и топлива. Масло стоит использовать исключительно 5W30, 5W40, желательно - рекомендуемое производителем.

Техническое обслуживание мотора N57 проводится каждые 15 тыс. км пробега. Сервисмены рекомендуют сократить этот регламент до 7-8 тыс. км.

Ресурс двигателя по оценкам владельцев и экспертов составляет 300+ тыс. км.

- Привод ГРМ также весьма надежен: цепь ходит в среднем по 200+ тыс. км.

- Турбина служит 200+ тыс. км, что весьма достойно.

Типичные неисправности

Двигатель N57 похож по конструкции и характеристикам на другие моторы N-семейства. У него также имеются специфические проблемы, характерные для данных турбодизелей.

Вихревые заслонки

В отличие от семейства M, здесь они рискуют не отломаться, улетев в двигатель - но закоксоваться и перестать вращаться. Как следствие - работа двигателя нарушается, на приборной панели владелец видит коды ошибок.

К такой ситуации приводит загрязненный клапан EGR. Его нужно регулярно чистить или заглушить. Часто владельцы сталкиваются с проблемой заклинившего клапана уже к 100 тыс. км. пробега.

Шум в подкапотном пространстве

Общая проблема с мотором N47, которая связана с износом демпфера коленвала спустя примерно 100 тыс. км пробега. Решение - замена детали.

Цепь ГРМ

Другая причина нетипичного шума из моторного отсека - на замену таким образом попросилась цепь привода ГРМ. Обычно это случается на пробеге порядка 200 тыс. км.

Итого

Моторы серии N57 - надежные мощные турбодизели, которые заслужили уважение автолюбителей по всему миру.

Если сократить рекомендуемый производителем срок обслуживания мотора вдвое, не экономить на расходниках и заправляться качественным топливом, N57 прослужит долго и порадует своими характеристиками владельца.

Не пропустите другие обзоры двигателей BMW N-серии:

Читайте также: